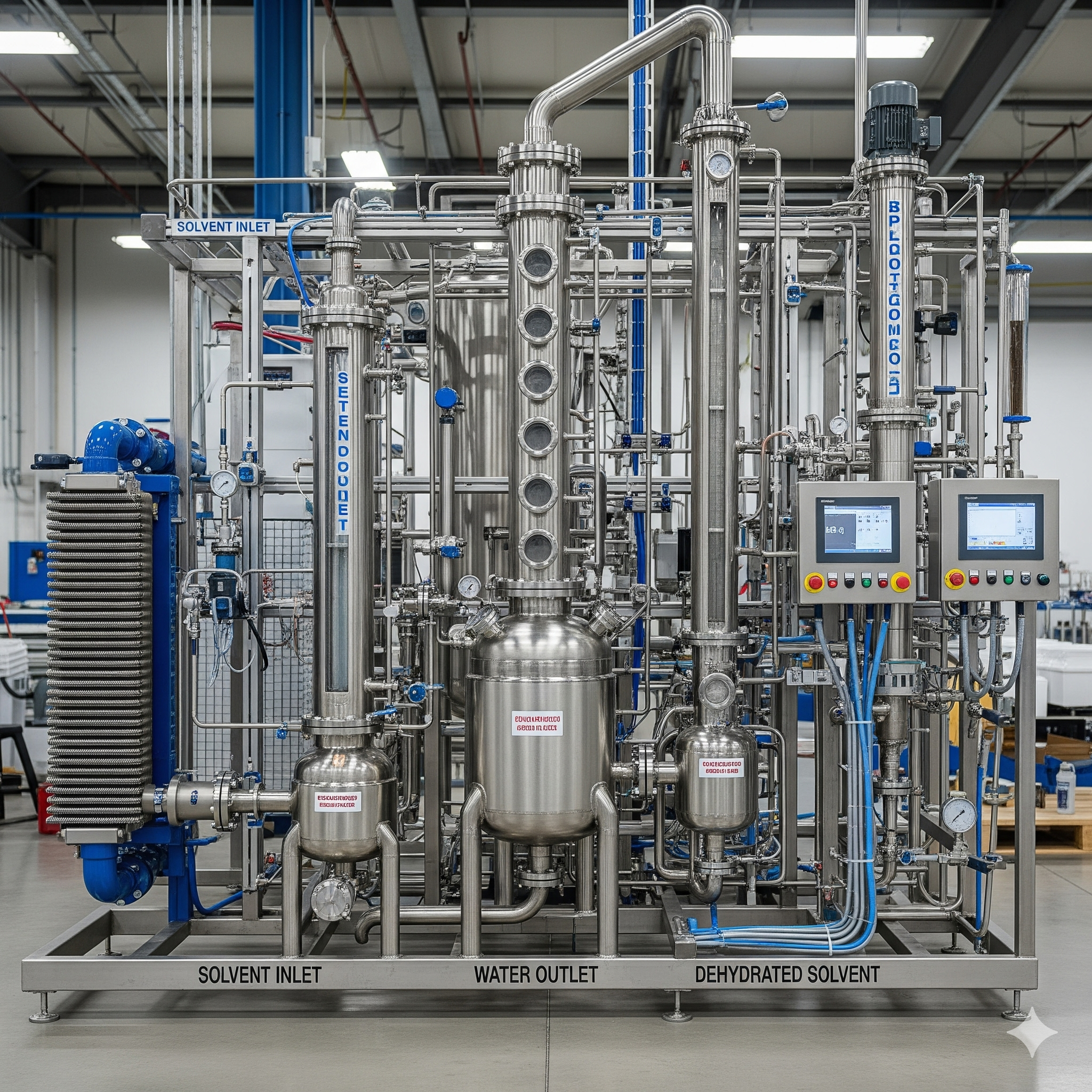

Solvent De-Hydration System

Nuberg Gas Plants Division , a Global leader in Gas Generation and Purification, is pleased to offer Solvent Dehydration systems based on Adsorption technology to provide Dry and Efficient Re-usable Solvents at an Economic cost.

Our Solvent Dehydation System

We at Nuberg have expertise in adsorption processes using Pressure Swing Adsorption (PSA) Technologies for over 30 years. As one of India’s fastest growing Global EPC organizations in the field of process plants and industrial gas plants, we have provided a diverse range of adsorption-based gas and liquid drying solutions to our customers across applications using the latest available technologies.

Molecular sieve-based adsorption plants provide an effective way to remove moisture from liquid solvent streams or gas streams. These plants can deliver final products with the lowest moisture content, and the dryness of the product can be tailored to meet the desired specifications.

Molecular sieve dehydration systems are well suited for solvents such as Ethanol, THF, MEK, and others that form azeotropic mixtures with water. Conventional distillation systems are limited in such cases as they are highly energy-intensive thermal separation processes. Molecular sieve systems overcome this challenge effectively.

Molecular sieve-based dehydration plants offer major advantages for the following reasons:

- To achieve dehydration objectives for organic solvents

- Dehydration of solvents forming azeotropic mixtures

- To achieve very dry solvents as product (up to 100 ppm or less)

- Energy-efficient plants in comparison to conventional distillation plants

- Easy to operate, continuous, and automatic operations

The basic design consists of two or more molecular sieve adsorber units. In a typical two-tower design, one unit is in operation (dehydration mode) while the other adsorber unit is in regeneration mode. Once the adsorber unit becomes saturated with moisture (state of equilibrium), the operations are automatically switched (using automatic switching valves) to the other unit, which has meanwhile been regenerated, while the previous unit undergoes regeneration.

The alternate mode of dehydration and regeneration in an adsorber is achieved with Temperature Swing Adsorption (TSA) technology. An inert gas stream is used for regeneration of the adsorber tower.

Key Features and Benefits

Use of High-Quality Materials

Built with superior-grade components for long-term reliability.

Separate and Independent Section Alumina

Ensures high adsorption efficiency and enhanced performance.

Advanced Technical Design

Incorporates modern engineering for optimized operations.

Special Design PSA Tower

Engineered to deliver consistent output with high durability.

Use of Quality Components

Equipped with trusted parts for smooth and safe functioning.

Easy to Use and Maintain

Designed for hassle-free operation and quick maintenance.

Multi-Functional Options

Adaptable to a wide range of industrial requirements.

Durable and Robust Construction

Built to withstand rigorous industrial environments.

User-Friendly Interface

Intuitive controls make it easy for operators to handle.

Portable and Lightweight

Compact design for easy transport and installation.

Compliant with Latest Safety Standards

Meets global safety benchmarks for peace of mind.

Increased Operational Efficiency

Maximizes output while minimizing energy usage.

Saves Time and Resources

Streamlined design reduces downtime and costs.

Enhanced Performance and Durability

Engineered to deliver long-term, consistent results.

Simple and Intuitive User Experience

Easy-to-navigate controls improve operator efficiency.

Cost-Effective Over Long Term

Lower operational and maintenance costs ensure savings.

Environmentally Friendly Option

Designed with sustainability and eco-compliance in mind.

High Safety and Reliability

Reduces risk with robust safety mechanisms and design.

Comprehensive Support and Service Availability

Backed by reliable after-sales assistance and guidance.

Applications Across Industries

Sustainability and Compliance

At Nuberg GPD, our Solvent Dehydration Systems are designed with sustainability at their core.We use energy-saving technologies, recyclable materials, and waste management practices that minimize carbon footprint. Designed for long-term efficiency, our solutions promote both environmental responsibility and economic sustainability. We also ensure full compliance with global standards. From safety and quality regulations to environmental laws and industry certifications, every system is rigorously inspected and audited. Customized to meet customer and market needs, our solutions deliver reliability, safety, and future-ready performance.