INTERNALLY HEAT REACTIVATED AIR DRYER

DESCRIPTION OF THE INTERNALLY HEAT REACTIVATED AIR DRYER

The Internally Heat Reactivated Air Dryer is a simple alternative for medium & bigger capacities where Heatless Dryers become uneconomical due to heavy purge losses. In this type of Dryer, the regeneration is accomplished with a very small portion of dried air/gas. This is circulated in the tower duly filled with desiccant and embedded with heating elements. The advantage of this type of dryer is that purge loss is reduced to almost 3 – 5%, and dew points up to (-) 80 °C can be achieved.

This is an improved version of the Heatless Dryer where purged air loss is low due to the fact that regeneration is achieved by dry air at low pressure and at high temperature. To achieve this heaters are provided in each tower to heat the purge air to around 180 Deg C, which enhances its moisture carrying capacities. This hot purge air at low pressure is passed through the desiccant bed to regenerate the Activated Alumina.

Nuberg GPD has a long standing experience of manufacturing Air Dryers for various industrial needs. We have been in the business for over 20 years, and are continuously expanding ourselves to provide the best service to our clients. We are under collaboration with CarboTech to bring you the highest quality products.

FEATURES

- Capacity: 200 CFM to 1000 CFM

- Dew Point: -60 to -80 deg C ADP

- Purge Loss: 5-10

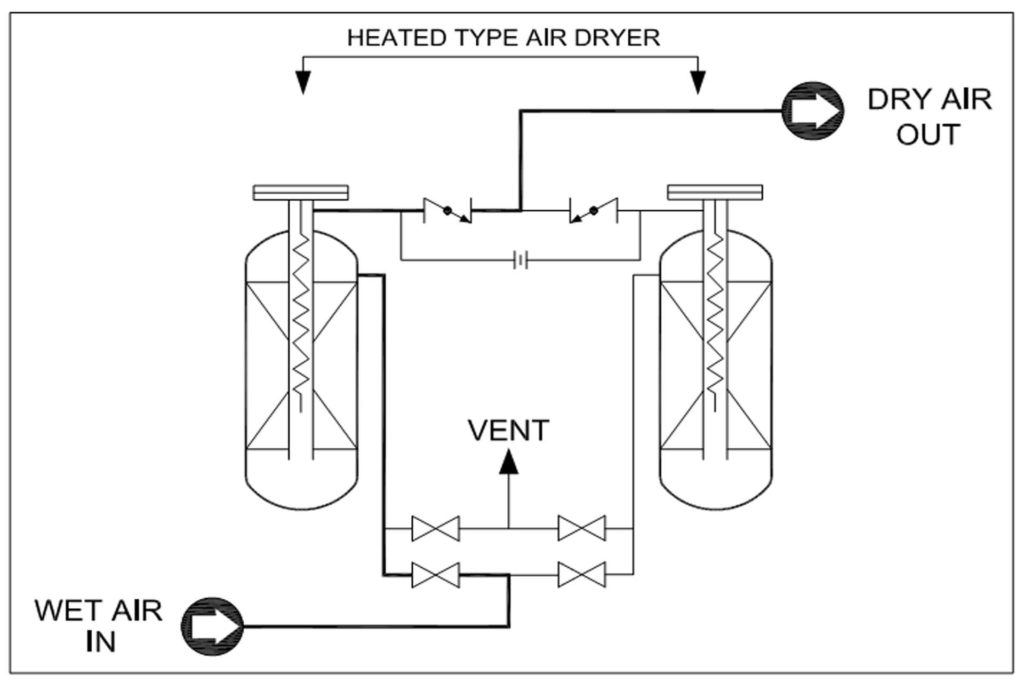

A typical representation for the plant is shown in the figure 2.0 belthis

APPLICATION

- Synthetic Fiber Industry

- Chemical Process Industry

- Air Curtains

- Other Miscl. Industrial Applications

SPECIFICATIONS

Product | Air Dryer |

Plant Capacity | 20 CFM to 500 CFM |

Purge Loss | 12-15 |

Dew Point | (-) 40 to (-) 60 deg C ADP |