NITROGEN COPPER DE-OXO MODEL

DESCRIPTION

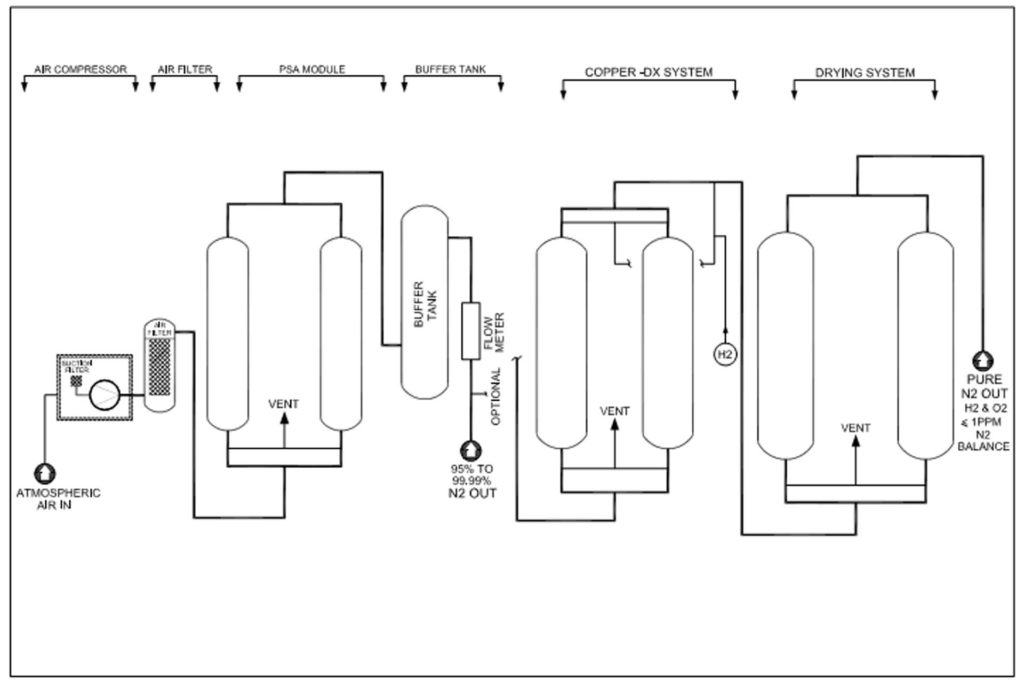

The Nitrogen copper DE-OXO Model unit is used for additional cleaning using a copper catalyst for the removal of extra Oxygen, moisture and Hydrogen contents, and maintaining 1PPM levels. This ultra-pure nitrogen gas finds application in electronic, synthetic fiber and optical fiber industries. These systems are installed where along with Oxygen and moisture, Hydrogen is not derived in the Nitrogen gas stream.

To know more about PSA Nitrogen gas plants, click here.

This DE-OXO model unit needs two externally heated filled columns with copper as a catalyst for an endothermic reaction. The loaded copper bed can be regenerated by adding Hydrogen during the regeneration step. For this two-step process (Deoxidization and regeneration), two reactors are necessary to achieve a continuously operating DE-OXO system. The nitrogen from the PSA System with the remaining oxygen passes to one of the reactors without adding Hydrogen. On passing through the reactor, the oxygen is removed through reacting with the copper surface. The advantage of the Nitrogen copper DE-OXO model is that the high purity nitrogen leaves the unit absolutely dry and without any remaining Hydrogen.

A typical representation of the plant is shown in figure 1.3 below.

FIGURE: N2-CUDOXO PLANT

APPLICATION

- Metallurgical Industry

- Heat Treatment / Annealing

- Synthetic & Fiber Industry

- Chemical Industries

- Pharmaceutical Industry

SPECIFICATIONS Of THE NITROGEN COPPER DE-OXO MODEL

Product | Nitrogen Gas |

Plant Capacity | 1 – 1500 NM³/Hr. |

Oxygen | 1 PPM |

Hydrogen | NIL |

Nitrogen | 99.9997% |

Dew Point | (-) 60°C to (-) 80°C |

Pressure | 5 ~ 25 Bar |

LOOKING FOR LOW MAINTENANCE, COST EFFECTIVE GAS GENERATORS?

TRY NUBERG FOR SAFE PRODUCTS THAT LAST A LIFETIME.